How to Choose the Right Grease Product for Your Equipment

Grease protects your equipment and extends its usable life, but not all greases are the same. In fact, using the wrong product could actually prove detrimental. Despite how common the use of grease is, many misconceptions remain. These misconceptions, such as all grease is the same and more grease is always better, can lead to performance issues and maintenance concerns down the road.

Choose the wrong grease and problems can range from minor headaches to increased maintenance costs, overheating, component seizure, corrosion, premature breakdown, and even catastrophic failure of the part that was intended to be protected. There is also always the risk of introducing harmful materials not intended for the environment, such as in marine or food applications.

Choosing the Right Grease

Every third bearing can be saved if you apply the right grease at the right place, at the right time, and in the right amount.

“Within the diversity of applications and operating conditions, grease users have to balance many needs when selecting the right grease,” explained Chris Herle, Lubricant Product Manager with Federated Co-operatives Limited.

Ambient and operating temperatures, coupled with base oil viscosity, play a role in determining which grease is right for a certain application. Additives can also have a positive influence on grease performance, with some having a greater impact than others.

The grease recommended by the original equipment manufacturer (OEM) will take things like load, speed, cost, specialized requirements, orientation of the equipment, environmental sensitivity, potential contamination, lifespan, lubrication system, friction and operating temperature into account.

“When choosing grease, you should consult the owner’s manual of the equipment in question and know the grease thickener type of the required grease,” said Herle.

“Choice of grease, including thickener type, additives and base oil used to make the grease will ensure the protected parts function at peak performance within the environment. Things such as pumpability, water resistance, consistency, dropping point, oxidation stability and temperature of the part and the environment are all variables that should influence choice of grease.”

A Quick Look at Grease Types

Here are some of the most common types of grease you might encounter and what sets them apart from each other:

Lithium Grease: For a long time, lithium greases were considered the standby multi-purpose grease. They have good mechanical and oxidative stability and provide corrosion resistance and antiwear protection. Lithium greases are a true multi-purpose grease for automatic and industrial applications, but they are usually limited by high heat, high loads or wet conditions.

Lithium Complex: Greases based on a lithium complex could be considered the new multi-purpose grease. Lithium complexes are high-temperature greases with outstanding mechanical and thermal abilities and resistance to water. They’re ideal any time there is a demand for higher performance and longer life than typical lithium greases. They’re ideal for on- and off-highway vehicles, wheel bearings and chassis applications.

Calcium Sulfonate Complex: These greases are great for heavy-duty applications. They’re high-temperature greases with a unique thickener system to deliver anti-corrosion and extreme-pressure properties. Their high-load carrying ability and water resistance make them a great choice for heavy construction and mining applications as well as corrosive marine environments. Calcium sulfonate complexes are often found in off-road vehicles, construction and mining equipment, and other heavy-duty industrial applications.

Polyurea: Polyurea greases come in a variety of versions, the two most common being toluene diisocyanate (TDI) and methylene diphenyl diisocyanate (MDI). TDI gives excellent mobility, sealing bearings from contaminants and preventing leakage. MDI is a shear stable thickener, increasing life and performance in rolling bearings. Both offer oxidation stability and corrosion resistance, which is beneficial for equipment subject to long periods of storage or infrequent use. You’ll find polyurea greases in high-temperature industrial and automotive applications, wheel bearings, and electrical motors.

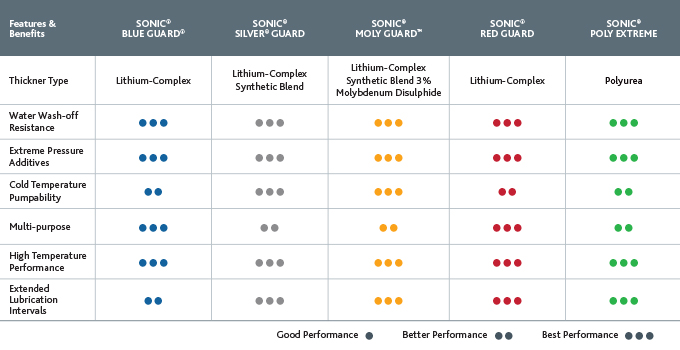

Co-op Premium Lubricants offer a range of greases designed to protect and extend your equipment life.