On-farm fuel storage has changed a lot in recent years. Tanks have been built with improved safety and efficiency, but proper maintenance practices are necessary to protect fuel inside.

While occurrences are limited, microbial contamination of diesel fuel can create challenges such as:

- plugged filters

- fuel flow problems

- injector malfunctions

- reduced combustion efficiency

- increased rates of corrosion

Microbial growth

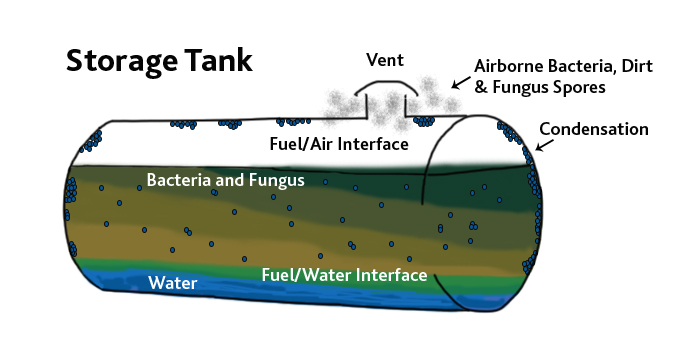

Bacteria and fungus cause microbial growth. Microbial growth occurs when water is in the storage tank and the diesel fuel temperature is between 10 C and 40 C. Bacterial and fungal spores commonly found in the soil can enter the fuel tank through vents on the storage tank or through contamination during filling. Condensation of water vapour within the fuel tank creates the conditions suitable for microbial growth at the fuel-water interface near the bottom of the tank.

The microbial growth and biomass production result in what appears to be a dark slime with an appearance of algae – some have even likened it to chocolate mousse. Under severe conditions, sludge accumulates on the bottom of the storage tank.

Prevention

The easiest way to prevent microbial growth is to limit the amount of water in the storage tank. Check tank bottoms for water every month initially, decreasing frequency if no water is found. Tanks should be checked for water at least twice a year.

Regularly drain water from the bottom of the fuel tank by mechanical methods or with drain plugs located at the bottom of the tank. Water leakage into underground storage tanks should also be prevented.

Equip fuel tank vents with filters to prevent bacterial and fungal spores from entering the tank. Periodic tank cleaning, maintenance and inspection should be scheduled. Treatment with an approved fuel preservative can help to control or delay the buildup of microbial growth. The frequency of fuel treatment will depend on how fast microbial growth builds up.

Control

Remove microbial growth by manually draining or chemically cleaning the tank. The use of a biocide may be necessary in combination with high-pressure washing.

When selecting chemical treatment, consider the compatibility with the fuel and other additives, environmental impacts and potential effects to equipment fueling systems.

Fuel filters on the storage tank and on transfer tanks will prevent slime or sludge from being transferred to farm equipment. Fuel transfer piping should draw fuel from the middle third of the tank to prevent sucking up of microbial growth or water.

If you suspect microbial growth in your on-farm diesel fuel storage tanks, talk to your local Co-op Fuel Team to find out how to submit fuel samples for testing and learn about remediation options.

Remediation Tactics

In the event of microbial growth, there are several tactics that can be completed to remediate the microbial growth contamination.

Multipoint Water Pumping ($)

In traditional fuels, a clear separation of fuel and tank bottom water is typical. Your service contractor can readily insert a suction tube to the bottom of the tank and pump the water out. It is advisable to pump water at all available access points from the tank. If it is determined that the pump or suction is at the lower end of the tank, the pump should be removed to facilitate water pumping at that point. Some specialty service contractors offer methods that use flexible suction tubes to remove water and loose contaminants from the entire length of the tank bottom. Care should always be taken to ensure that the tank bottom waste is disposed of properly.

Fuel Polishing ($$)

Fuel filtration and polishing include methods that remove water and contaminants from the fuel without removing the fuel from the tank. Some vendors use fibre-optic technology or remote video cameras to visually locate and observe the contaminate removal progress. Others use a variety of fuel circulation techniques to filter the water and contaminants out of the fuel.

Non-Entry Tank Cleaning ($$$)

There are several vendors that offer services to clean a tank without physical entry. Typically, these techniques require the fuel to be removed from the tank and equipment is lowered into the tank to remotely pressure wash it. Some vendors supplement the washing process by using a remote video camera to monitor the progress. These techniques require contaminated wash liquids and solids to be disposed of properly.

Physical Tank Cleaning ($$$$)

In cases where it is determined that the amount or severity of the tank contaminants is extreme, a manned entry cleaning may be required to clean the tank adequately. Manned entry allows for the entrant to physically scrub contaminants from the tank wall. Physical tank cleaning is typically used only by commercial fuel marketers.

For small tanks (less than 1,000 litres) with severe fouling, replacement may be more practical than cleaning. This is for extreme cases with heavy slime buildup.